Lean Production Optimization of a Company's Engine Brake Production Line

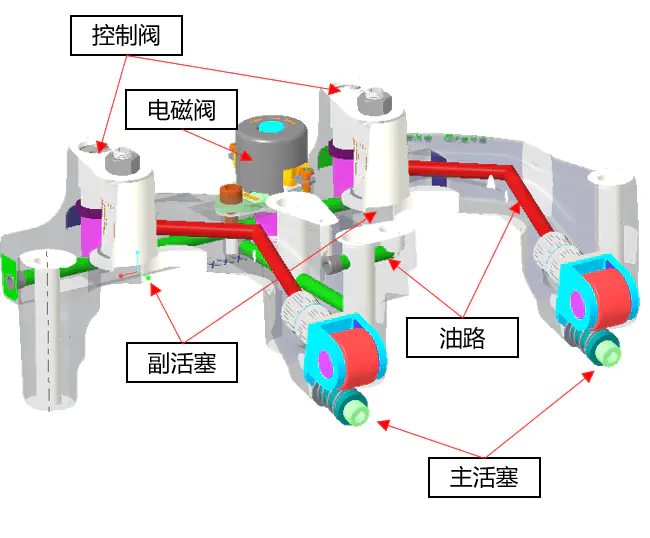

YUCHAI K8 Brake

YUCHAI K8 BrakeAward: This project won third prize in the 15th Tsinghua University ‘NISSAN Cup’ Industrial Engineering Competition.

Introduction

X company has a 50-year history in engine retarding for the heavy and medium high-speed transport vehicles and diesel engine markets. In December 2019, the orders of YUCHAI project (K8, K11, K13) exploded, and the company’s current production capacity could not meet customer demand. In order to meet the surging demand of customers and achieve a higher market share in the competition, the company needs to achieve a 100% on-time delivery rate to meet customer demand.

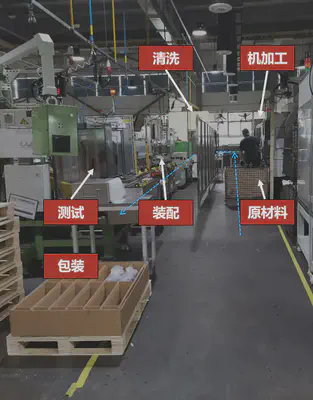

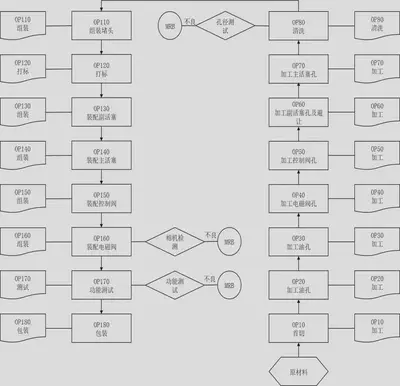

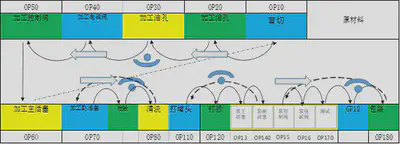

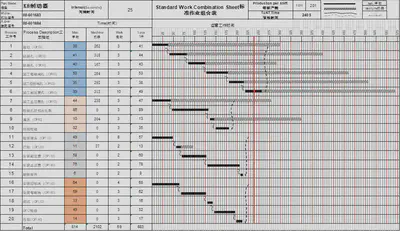

Current Situation of K8 Production Line

Before the optimization, the cycle time of this line was 2916 s, maximum daily capacity was 201 pcs; however, the required takt time was 240 s, which means eight operations could not satisfy the requirement.

Optimization Result

After the optimization, the daily output increased to 306 pcs.

My Contribution

- Production data collection and tabulating

- Report writing